Engineering, Design, and Project Management

Engineering

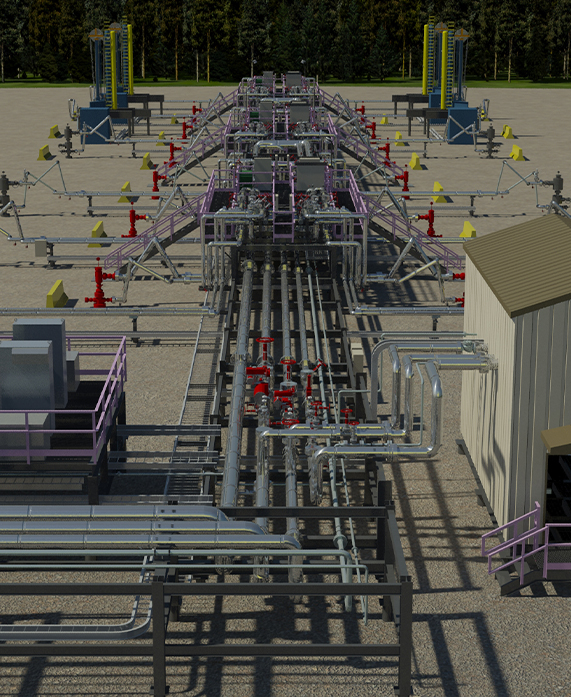

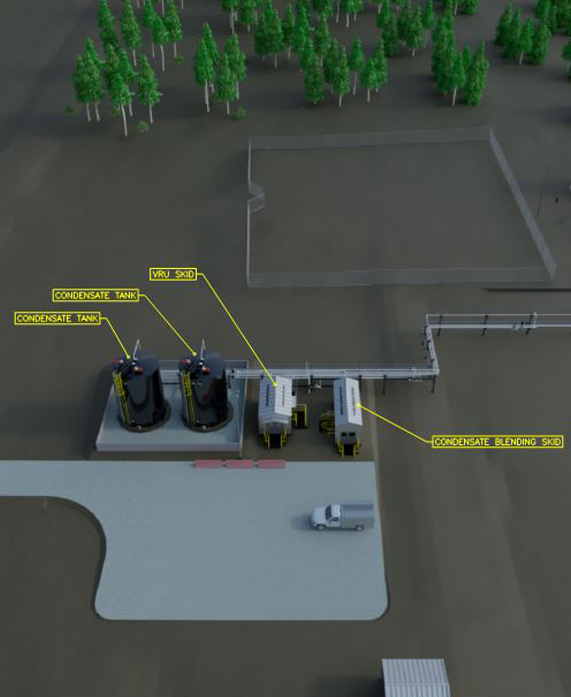

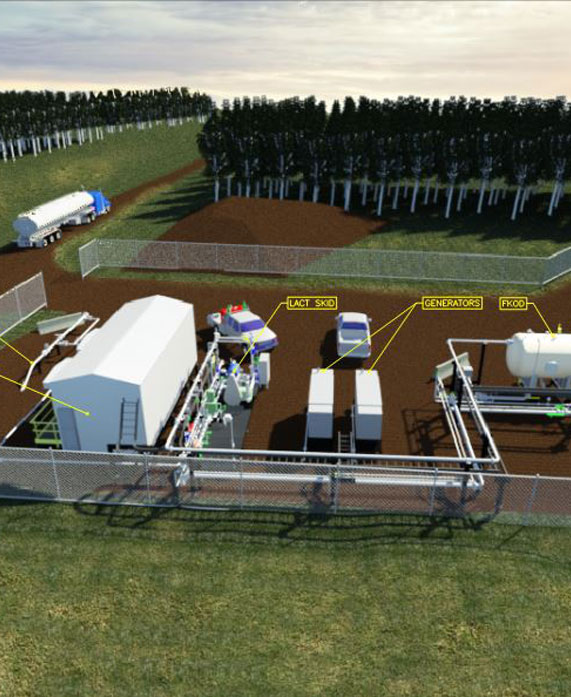

From Concept to As-Built

Our team of expert engineers work with our clients during all stages of a project to ensure quality and long-term success.

Our in-house disciplines include:

• Process Engineering

• Mechanical and Stress Engineering

• Rotating Equipment Engineering

• Electrical and Instrumentation Engineering

• Design and Drafting

• As-Building

• Reality Capture

Our areas of expertise include:

• Thermal/SAGD

• Conventional Oil Processing

• Refining

• Waste Heat Recovery

• Sulfur Plants

• LACT

• Butane Blending / Product Blending

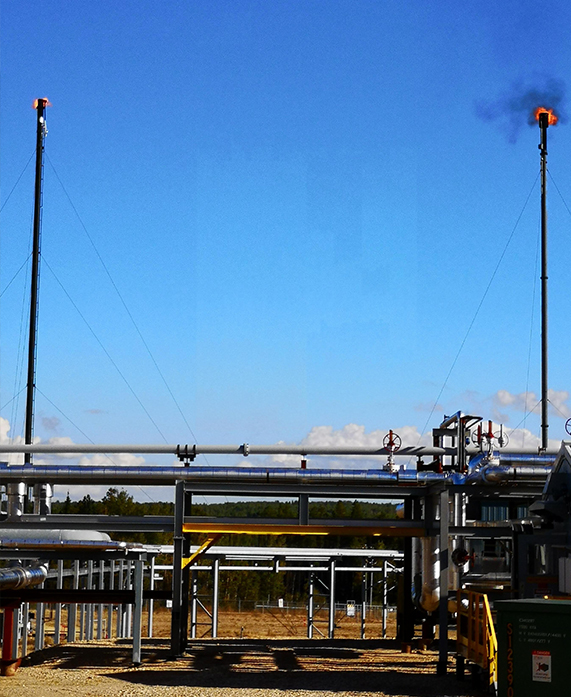

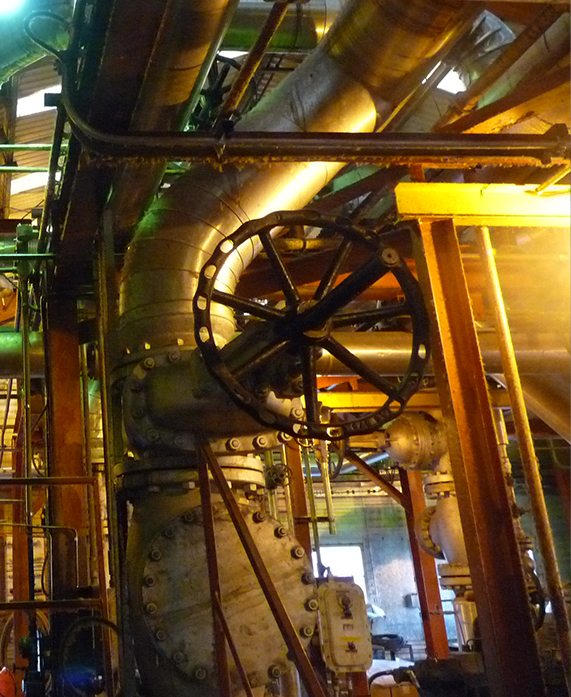

Site Services

See It to Believe It

Our site services team has a deep understanding of field and facility operations.

We have extensive experience executing:

• Operations and Maintenance (O&M) Capital

• Management of Change (MOC)

• Brownfield Debottlenecks

• Turnaround Project/Technical Support

• Sustainable Capital Programs

• Small Development Capital Programs

• FEED/Scoping

Project Services

Success Starts with a Plan

From the most simple to the most complex, SWAT has the expertise and experience to manage a variety of project requirements.

Our specialties here include:

• Project Management

• Procurement Services

• Scheduling

• Cost Estimating

Our Story

A story of value, performance, and integrity.

Value is our focus, performance is our promise and integrity is our foundation.

SWAT provides expertise and capability for conventional oil and gas, midstream, and SAGD facilities in niche areas using an integrated approach with owner companies.

The SWAT concept was brought to life based on creating and sustaining long-term value for clients/owners in specific niche areas of the oil and gas industry, which have a long-term focus or need towards operational value.

The SWAT team is in place to help clients/owners reach success in executing specific facility-based projects and capital portfolios by bringing qualified and versatile people together in a tight-knit environment, with an execution structure that is built around efficiency and strategic relationships.

With a focus on a niche area of business where clients require long-term help and support, SWAT has developed a simple structure geared towards cost-effective delivery with more consistency and trust built with clients.

Past Projects

“The best compliment is repeat business.”

Fit-for-purpose execution, accountability and talent.

We believe the focus on these three elements has been lost or diluted in traditional execution models. For a firm to be successful in this niche platform, these three ideas need to be the core focus of that company. The fit-for-purpose approach, people, systems, and culture must be geared towards optimal execution.

It must be the identity of the company, not a side arm or spin-off.

Our focus isn’t multi-billion dollar facilities or pipelines that run coast to coast. Our bread and butter is the type of project that impacts your operations day-to-day and long-term.

Whether it is debottlenecking a facility, adding compression in a field asset, or a simple service such as cost estimating, it is our CORE business, and we will stick to it without the growth distractions from large projects and market swings.

Our Locations

“We’d be more than happy to help you.”

Whitecourt Office

4105 41 Avenue

Calgary Office

5040 12 A Street SE

Calgary Alberta

Our Clients

“The best compliment is repeat business.”

Join the Team

“Always Leveling Up”

Join the Team